Today, half of the build team got together and did a little extra work for our skeleton prototype. No session is complete without a trip to home depot, roaming the isles aimlessly looking for bolts, wood, and nails. After purchasing all the things we needed, we got to work. Although we didn't have all the tools needed to work, we made headway on our Z table and on a DIY vacuum former. The vacuum former will be used to help the process of molding the UV blocking acrylic for the top hemispheres of the machine.

Saturday, November 30, 2013

Thursday, November 28, 2013

Mounting Suspense

Posted on 11/28/2013 09:01:00 PM by Unknown with No comments

The AutoCad team has completed the first milestone! The preliminary prototype drawings were due on November 20th and the team had them done just in time. Since the prototype drawings are now completed, the build team came together once more, only to split off again into various partnerships to work on different aspects of the prototype. These groups have the tasks of working on: a Z mock-up with parts, the machine base, resin pool, and projector mounts.

Even though the class is on break from school for the Thanksgiving holiday, the build team is still working hard. We have arranged for a full build team meeting outside of school to continue our work.

The next milestone is to have the skeleton prototype by December 4th, and at the pace we're working it, shouldn't be a problem! And then, we're up to bat in the big leagues with our first full scale working prototype.

Even though the class is on break from school for the Thanksgiving holiday, the build team is still working hard. We have arranged for a full build team meeting outside of school to continue our work.

The next milestone is to have the skeleton prototype by December 4th, and at the pace we're working it, shouldn't be a problem! And then, we're up to bat in the big leagues with our first full scale working prototype.

Tuesday, November 26, 2013

All Eyes on EYE

Posted on 11/26/2013 07:51:00 PM by Unknown with No comments

In early November we were asked by Kara Rosettie to give our “Why LEGO” presentation at the Dorothy Nolan HSA meeting. The presentation was a great success and the parents and teachers were very excited to be piloting the LEGO Club in their school. As a result of the presentation five hundred dollars was granted to the LEGO Club to purchase supplies. The LEGO Club will be staffed by Dorothy Nolan parents and Inventeam club members and we are enthusiastically anticipating the LEGO Club kick off day on December 4.

Over at Geyser Road Elementary School Mr. Baldwins fourth grade class has started using the LEGO WeDo programming software. Unfortunately, every student in the classroom does not get ideal programming time due to our our shortage of laptop computers. For this reason we completed the Saratoga Foundation for Innovative Learning grant application and requested for a five thousand dollars so that we can purchase a cart of ten laptops for the students to learn programming on. Next year when elementary engineering becomes more widespread the computers can be used across the building for students to learn programming and design on.

At Lake Avenue Elementary School we are preparing for the launch of the Project Lead the Way Elementary Pilot. There was an elementary engineering education teacher training day held on November 20. The teachers are very excited to begin engineering education in their classrooms. Now we are just working on scheduling in engineering time into the classroom schedules. Once the schedules are all set up we will be able to begin the pilot!

To supplement grant money and Inventeam funds, we have also been working on EYE fundraisers. Impressions of Saratoga has generously allowed us to sell laser cut ornaments and magnets in their store to help us gain funds. We hope that the funds that we raise from these ornaments will be enough to purchase the Inventeam t-shirts with the EYE Logo so that we all have a uniform shirt to wear at the major fundraiser that we are setting up. This main fundraiser is the Educating Young Engineers Saturday program! We will be hosting an engineering day at the Saratoga Springs High School for students in first through fifth grade. We are planning on having four fun engineering challenges for them to complete throughout the day! In the upcoming weeks we will work to plan this day and get students to sign up! As a start we have created an EYE website with the registration form for parents to sign up their children on and so that parents will be able to find out more about EYE. If you would like to visit our website you can click on the following link! (https://sites.google.com/site/educatingyoungengineers/)

Overall, we have had a very busy and successful month and will continue working hard to make the elementary engineering programs have a positive impact on as many students as possible!

Friday, November 22, 2013

Software Progress

Posted on 11/22/2013 04:44:00 PM by Unknown with No comments

Over the past few

months, the software team has made exceptional progress. We have added many features to the user interface such as a file

chooser, a custom spin control for touch applications, and a gear generator.

The gear generator takes in user parameters and then can determine the exact shape of a

gear with various types of teeth. With this feature, we hope this that this will now help to

both improve ease of use for basic things and save time for the user. Another great

accomplishment of the software team was the completion of a configuration file

that will allow the user to change different settings such as the layer depth

or the color of background and have these settings saved. The user interface

also has a user-friendly bubble menu for selection that can be used directly

from the printer, allowing the user to make changes or create a product without switching to a desktop. Finally, our group has also made huge advancements in writing a stepper

motor class to control the Z table. With help from the electronics team, the software team has now

created a program that can control the stepper motor and the different outputs of

the microcontroller. This is just the beginning of a vast range of accomplishments for us, and they can only grow from here.

Monday, November 18, 2013

A Sticky Situation

Posted on 11/18/2013 10:47:00 PM by Unknown with No comments

Recently, the focus of the materials subset of the build team has been developing an auto-refill system. The team has spent a lot of time testing a peristalsis pump in order to efficiently use left over resin in an automatic refill system. The pump is hooked up to a power supply and by reversing the motor, can easily transfer liquids from one area to another, something ideal for an auto-refill and drainage system. The strongest challenges have come from avoiding the cross contamination of the different resins. In order to use multiple resins, we have to ensure that they do not mix as every resin has a different chemical makeup. This has set up a sticky situation because the resin sticks to almost everything making some equipment hard to clean, especially with the peristalsis pump. Some solutions include using a separate pump for each resin, removing the pump and cleaning it by hand, or lining the tubing of the pump with a nonstick coating such as Sylgard 184. We will be able to make our first complete design for the refill system by the end of the week. We also will start to figure out how we will integrate the system into the rest of the 3D printer over the next week. Another portion of the team has been focused on ordering parts, within our budget, for not only the build team and CAD team prototype but also a separate open source Do it Yourself 3D printer that a few team members are working on outside of the classroom. As more ordered parts of the printer come in we will be able to make the CAD teams design come to life.

Sunday, November 17, 2013

Fundraising, Food, and Fun

Posted on 11/17/2013 09:40:00 PM by Unknown with No comments

On November 4, we had our first successful fundraiser for the Saratoga Inventeam! This was held at 99 Restaurant who allowed us to have 15% of the proceeds from the bills of people who came in with one of our fliers. Also, to raise extra money, many local companies donated items for raffle baskets that we raffled off that night. It was so fantastic to see local Saratoga business's helping us out in reaching our end goal. Overall, the event was a success and we couldn't thank everyone enough for their help.

Additionally, the marketing team has been researching the possible name of our 3D printer and this will be announced in the next week or so! Stay tuned for the announcement!

Thursday, November 14, 2013

Keeping the Current Flowing

Posted on 11/14/2013 06:53:00 PM by Unknown with No comments

In the past month, the electrical team has made terrific progress. All of the parts we ordered have arrived and they have all been working smoothly. With this step now done, we have started some prototyping. In conjunction with the build team, we have built a setup that will allow the stepper motor for the z-table to move. We will be able to run this set up when the programming team creates and debugs the code to move the motor as desired. We have also been working with the build team in order to test the projector and to make sure the design files will allow our two groups to integrate our systems with the physical components. After testing the curing of the resin with the projector a class ago, it has become apparent that the projector has a UV filter inside of it which will need to be taken out before any further progress is made in that area.

In addition to all of this, we will be helping the programming team with their test program of a blinking light that will hopefully allow them learn a bit more about the code library that they will be using. At this stage of the project, working and collaborating with the other groups is a integral part of our job. Considering our progress so far, the final result should be very impressive.

In addition to all of this, we will be helping the programming team with their test program of a blinking light that will hopefully allow them learn a bit more about the code library that they will be using. At this stage of the project, working and collaborating with the other groups is a integral part of our job. Considering our progress so far, the final result should be very impressive.

Tuesday, November 12, 2013

Coding Bubbles

Posted on 11/12/2013 05:40:00 PM by Unknown with No comments

In order to make three dimensional printing accessible to a wide range of people, the programming team is working on making software that is both powerful and intuitive. In addition to working on a desktop computer, like most 3D printer software, we want our software to be able to run on the touchscreen embedded in our printer. In order to make an application that was touchscreen friendly, we needed to make menu systems beyond those available with the standard GUI frameworks. We developed a “bubble menu” system, similar to those seen on some soda machines. The bubble buttons are aesthetically pleasing, and offer a better target for a finger than the standard rectangular buttons supported by most frameworks. The menus can support up to nine elements, and dynamically rearrange based on the number of elements they contain. Our bubble menu concept gives our software a unique look, while improving customer interaction.

Other features we are pursuing make it easier for a user to print a part. We will give users the option to skip the advanced setup, and print parts with as little effort as possible. One way we will do this is through the use of editable templates. Some parts will have a dynamic layout, in which the user can add and remove lines, and edit specific coordinates. Other parts, such as a gear, can be generated automatically from values such as pitch, bore size, and diameter. Our first template is a gear template, which can generate gear with triangular, rectangular, trapezoidal, or rounded (sprocket) shaped teeth. This gear generator was the focus of much of the past two weeks of work. In order to generate the gear we had to create an algorithm, or set of executable steps, to make a list of points around the gear. The development of a process that could make gears with teeth of various shapes required knowledge of geometry, trigonometry, and computer science.

Sunday, November 10, 2013

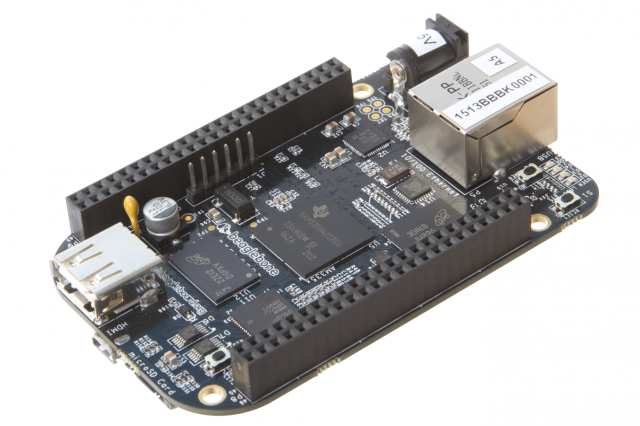

A Beagle Without Bark or Bite

Posted on 11/10/2013 08:40:00 PM by Unknown with No comments

Our electrical team has finally gotten hold of a BeagleBone Black, a type of microcontroller that will act as our machine's Central Processing Unit (CPU). Over the next few months, our work will involve connecting motors and peripheral devices (motors, sensors) to the BeagleBone and syncing them up with each other. This will require research into microcontroller programming, field testing the devices, and a lot of collaboration with the build and software teams. As of now, however, the electrical team will focus on ordering parts and planning their budget/schedule.

Thursday, November 7, 2013

CAD Team, Assemble!

Posted on 11/07/2013 08:08:00 PM by Unknown with No comments

The CAD Team has been making very steady progress. Over the past few classes, we have been discussing more design ideas regarding the automatic refill/ draining system. Seeing as it was an idea that came about very early while brainstorming, we have recently gone back and evaluated its feasibility and whether this would be a beneficial innovation. After discussion with the rest of the Build Team, we decided that we are going to implement it into our design. However, it will have to be scaled back in our initial prototype from being able to store multiple types of resin to just one. Once we are able to successfully create a working automatic refill/ draining system we will add a way to hold more than one resin type. Before the beginning of next class this system will be added to our assembly. As we progress further into the assembly for our 3D printer design we can start to see how each of our individual parts are make up the grand machine, like pieces to a puzzle.

The CAD team also finished working creating parts for the Instructables 3D printer using the .idw files provided by the guide. We are currently assembling this printer on Autodesk Inventor, and once it is completed our task-force in charge of creating this will begin their build phase.

Tuesday, November 5, 2013

Going LEGO

Posted on 11/05/2013 10:47:00 PM by Unknown with No comments

The past two

weeks have been very exciting for the elementary engineering group! On

Wednesday October 23, we met with the teachers who are participating in the

LEGO engineering at Geyser Road Elementary School and trained them on how to

use the LEGO WeDo kits and software. With the teachers trained and equipment

ready we kick started the LEGO program on October 30th. The LEGO engineering

session went amazingly and the students announced that LEGO Wednesday’s were

their new favorite day. With a such a successful start to the LEGO engineering

program we are looking forward to starting the LEGO Club at Dorothy Nolan

Elementary School. We met with the club organizer, Kara Rossettie to make sure

that we were all on the same page with our expectations for the LEGO Club. We

are preparing to give a presentation at the HSA meeting at Dorothy Nolan

Elementary School on November 4th to gain funding for the LEGO Club. Once the

funding is secured Mrs. Rossettie will be able to purchase the supplies. We are

expecting the start date for the LEGO Club to be November 27th.

In addition to getting the elementary engineering programs

underway, we have been looking for additional ways to fundraise so that these

programs can continue and expand into next year. Over the next week we will be

designing laser cut ornaments and magnets to sell at local businesses to raise

a fraction of this money as well as applying for grant money from local

organizations.

Friday, November 1, 2013

Making Progress

Posted on 11/01/2013 08:46:00 PM by Unknown with No comments

Due for today, each group had to create a progress report detailing their groups accomplishments, research, and challenges. It was interesting to reflect on what one month of work has brought us to. Looking at all the research we have already completed, it isn't hard to tell why we've made the progress we've made. Of course, there is still a long way to go as we tackle all the challenges covered in this month's progress report write-up. Also, the progress report didn't just show our current standing in our work, but it puts the element of time into perspective. Before we know it, it will be the end of the year and we will be presenting a final, working model to the public. However, first things first: more testing and then after thanksgiving break beginning to work on our first functional prototype.

Subscribe to:

Posts (Atom)

.JPG)

.JPG)