Currently, EYE is working on the final

preparations for the December 6th “Engineering Athletics” Saturday

Program as the date quickly approaches.

We are finalizing student and teacher volunteers as well as getting

excited for the program. We are also in

the later stages of planning the December 13th “All about

Engineering” program with Ballard School in South Glens Falls. We are working with Shen to continue planning

their “All about Engineering” event in January.

We have been developing our Sponsor a Young Engineer program, which

accepts donations to cover the fee waivers of students who cannot afford to pay

for the Saturday Programs themselves.

EYE expects to have a successful turnout at all of these events and we

are excited to work with the community and interact with local students. EYE has continued to support the Dorothy

Nolan LEGO club and maintains the goal of becoming a 501(c)3 non-profit

organization.

Friday, December 5, 2014

Ready, Set, Go! Engineering Athletics

Posted on 12/05/2014 10:14:00 AM by Mike Gyarmathy with No comments

Nitinol Group is Still Doing Their Homework

Posted on 12/05/2014 10:14:00 AM by Mike Gyarmathy with No comments

Over the course of our last several classes, we have continued to reach out to Nitinol professionals

seeking any useful advice they may have. We also researched other types of shape memory

alloys, including Flexinol. These different SMAs (Shape Memory Alloys) are composed of various

metal mixtures. One model of heat engine we are looking into consists of two different sized gears and a chain made partly of Nitinol that connects them. The linear deformation of the Nitinol

causes the gears to spin. This is known as the VT1 engine. Another model we have

learned about consists of pulleys and belts of Nitinol. One belt of nitinol wraps around two pulleys, one being slightly larger than the other. The temperature differential produces a spinning motion. Several pairs of pulleys are set up in a like and connected by the axes of the pulleys, allowing constant rotation. Our plan is to continue learning about these as well as other existing models of Nitinol engines in addition to Nitinol itself. We are going to temporarily ignore the application side of the project so we can focus more on the development of an engine.

seeking any useful advice they may have. We also researched other types of shape memory

alloys, including Flexinol. These different SMAs (Shape Memory Alloys) are composed of various

metal mixtures. One model of heat engine we are looking into consists of two different sized gears and a chain made partly of Nitinol that connects them. The linear deformation of the Nitinol

causes the gears to spin. This is known as the VT1 engine. Another model we have

learned about consists of pulleys and belts of Nitinol. One belt of nitinol wraps around two pulleys, one being slightly larger than the other. The temperature differential produces a spinning motion. Several pairs of pulleys are set up in a like and connected by the axes of the pulleys, allowing constant rotation. Our plan is to continue learning about these as well as other existing models of Nitinol engines in addition to Nitinol itself. We are going to temporarily ignore the application side of the project so we can focus more on the development of an engine.

Thursday, November 20, 2014

Group Two has Picked a Project

Posted on 11/20/2014 09:56:00 AM by Mike Gyarmathy with No comments

Our EDD class split into

two groups. One group has worked on a

Nitinol engine, and my group has worked on several other several other

ideas. Group 2, consisting of Chris

Engborg, Shibo Jiang, Jordan Klapp and Rob Spzak initially focused on the concept

of building an RFID card. The two main

thoughts were to either make the card store general information such as name,

address, phone number, medical info ect.

The other option, would have been to build a card for use in schools

that preform a variety of different tasks such as checking out library books,

preforming lunch transactions and keeping track of attendance. To look farther into this, we each downloaded

Netbeans, a program that codes with databases.

After working with the program we found we were left with more questions

than answers. We also wondered whether or not there would be a market for such a technology.

Putting this idea to the side, we started

brainstorming other topics. We considered designing a gps that could be mounted on your bike and powered by pedaling. Unfortunately, pedal powered charging devices

already exist, and even have battery storage.

We then proceeded to look further into a few

more ideas. We wanted to focus on things that could be useful in everyday life, and have a broad market. One idea was an easy way to remove lint from

a hairdryer. Another potential project might be, a dryer machine that tests for dampness, drying clothes perfectly

and fully.

Finally, we have come up with two

ideas we will decide between, to be our final project. The first idea, is an

electric bicycle that would use some of the energy from pedaling and

regenerative braking to charge a battery that would be attached to a motor,

allowing the rider to get an extra speed boost when riding up hills or

just when it was convenient. Our other

idea was some sort of box that, once the user inputted the settings, would be

able to grow a variety of plants automatically.

The user would have to add soil and a seed to the device and they would

need to regularly fill up a water reservoir.

This idea will allow people to grow produce organically in their own

home at any time of the year regardless of the season.

As of today, we decided to pursue the plant growing

box as our project for the year. It will

present a unique challenge with the pairing of electronic elements to various mechanical

elements of the system. We eagerly accept the challenge and are ready to get to work.

EYE Founders Have Smoothly Passed the Torch

Posted on 11/20/2014 09:54:00 AM by Mike Gyarmathy with No comments

In the past few weeks, EYE has effectively launched the first sessions of the second year of Dorothy Nolan’s LEGO Club and has continued to support Division Street’s STEM Club. As the December 6th Saturday “Engineering Athletics” Program approaches, we have continued to plan and finalize arrangements with the local community. With the event already full, we expect to have a successful outcome. The students are very excited to participate and the parents and teachers are eager to make this event a special one. Shenendehowa currently is being aided by EYE for their Saturday Program in January and EYE is also helping Ballard Elementary school plan their upcoming Saturday Program on December 13th. Our future schedule includes planning for our 2015 Saturday Programs and continuing to expand and aid schools with Saturday Programs and LEGO Clubs. We are also planning to start the process of becoming a 501(c)3 non-profit organization and continue to excite the young engineers of the future!

Nitinol Progress

Posted on 11/20/2014 09:53:00 AM by Mike Gyarmathy with No comments

We are

in the process of brainstorming specific applications for the engine.

Some ideas include using the engine in a car to capture waste heat from the car’s

engine, and capturing waste heat from industrial ovens. We have been modeling different engines on

Autodesk Inventor and picked one to prototype. We dimensioned the pieces

to fit size and functionality parameters. We started building the prototype

from various materials, including plastic, wood and metal. The pieces were cut using the laser cutter, ensuring measurements are precise. An initial prototype would serve to produce much needed data on potential efficiency and load bearing capabilities for Nitinol engines. After a short time, it became evident that the materials we chose for the prototype were inadequate. Flimsy plastic parts left too much room for error. We decided to build a more professionalized prototype, sacrificing time and energy for a more quality product. This would hopefully have been worthwhile, making our lives easier during testing, and making our data more accurate. We came up with more potential sturdier adaptations of our design, each with varying levels of complexity. Unfortunately, after reaching out to professionals in the Nitinol community, we came to find our initial interpretation of the patent was inaccurate. Nick, our project manager has found a credible collection of research information. Today in class he gave our group a PowerPoint presentation, bringing everyone up to speed on some more complex Nitinol concepts. The source discusses many heat engine designs in depth, including the one we prototyped. After finding our prototype to be incorrectly designed, we regroup, continue to do more research, and for now we have put the prototype on the backburner.

EDD Off to a Strong Start

Posted on 11/20/2014 09:53:00 AM by Mike Gyarmathy with No comments

The year is

off to a great start in EDD, the class has gone through a series of steps

necessary in bringing about the beginnings of a successful project. Students have voted, electing their

classmates to reside over certain responsibilities for the class. Among these positions are treasurer, project

manager, blog coordinator, and fundraising coordinator. Nick Abate has been elected project manager,

Emily Verhag will be our treasurer and Eric Von Alman will be overseeing

fundraising. After conducting elections,

we presented and researched the feasibility of ideas initially brought into the

class as part of EDD's application requirement.

After some deliberation, the class settled on the design of a Nitinol Heat Engine. Nitinol is a Nickel-Titanium alloy, with

super elastic and shape memory properties. \These properties may be exploited, wherever a temperature

differential is present in order to convert waste heat into electrical

energy. Since making the decision to go with Nitinol, the class has split into thirds. While one group will pursue Nitinol and another will continue EYE, the last is still contemplating different ideas. Serious consideration has been given to innovations in the way of RFID technology, but the group is keeping their minds open to other ideas.

Thursday, June 12, 2014

The Final Countdown and Showcase

Posted on 6/12/2014 11:01:00 PM by Unknown with No comments

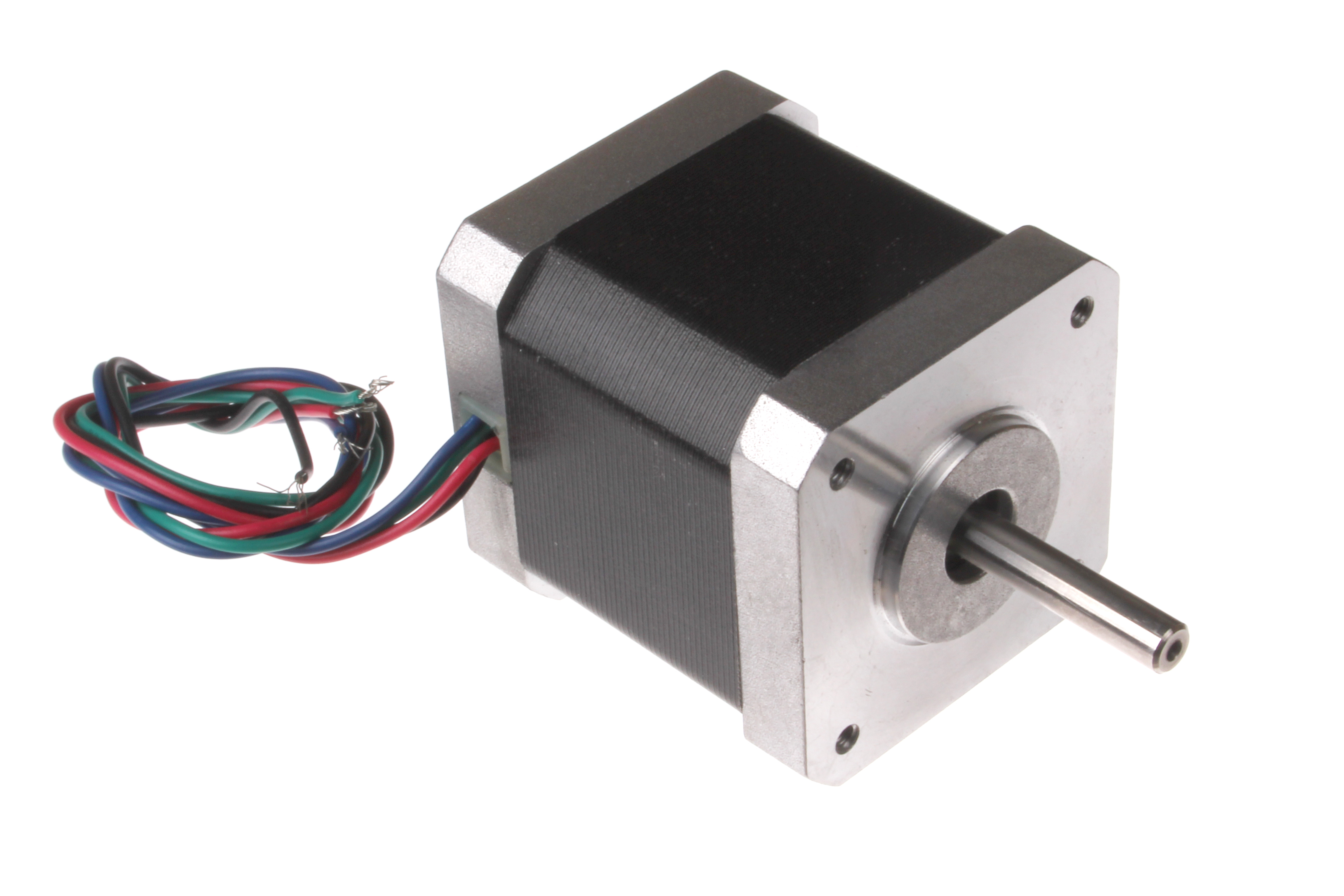

There is only one class remaining until our final showcase. Stress levels are high and nearly palpable for everyone in the room as we make the finishing touches on our presentation and on Charlie. A few different part on the printer had to be switched out a few days ago to make the Z-Table assembly as a whole stronger. One thing we ordered is a more powerful, stronger, stepper motor. Hopefully this resolves all issues and we will be able to print tomorrow. If prints run reliably, we hope to be able to do a live print at our final showcase. Also, Charlie has been given a rock-star makeover just for the occasion!!

Our final showcase will be held at Saratoga Springs High School (in the Teacher's Auditorium) at 5:30 pm on Tuesday June 17th. Further information and directions to the TA can be found on the new page titled "Final Showcase"

Our final showcase will be held at Saratoga Springs High School (in the Teacher's Auditorium) at 5:30 pm on Tuesday June 17th. Further information and directions to the TA can be found on the new page titled "Final Showcase"

Tuesday, June 10, 2014

Racing to the Finish Line

Posted on 6/10/2014 08:01:00 PM by Unknown with No comments

Now that the end of the year is rapidly approaching, the Educating Young Engineers team is working to finish strong and tie everything together. We are hosting another Saturday Engineering Program at the high school on June 14, titled “Engineering Athletics” that will demonstrate the parallels between problem solving and sports. We have been given great support for this program from the Engineering Design and Development class and will share the proceeds from the program with the EDD team. In addition the Yearbook committee is contributing a significant amount of volunteers so we will also be making a donation to the yearbook committee. Overall we are very excited for our upcoming program! We are also working hard on our final presentation. We will be doing a presentation on all of our accomplishments on June 17th at the Technology Showcase Night, and are looking forward to hopefully seeing lots of excited young engineers from our programs at the big presentation. We are also looking towards the summer, and making plans for what we will accomplish before the start of next year, so that EYE can hit the ground running in the 2014-15 school year.

Wednesday, June 4, 2014

Charlie's Wiring Squad

Posted on 6/04/2014 09:35:00 PM by Unknown with No comments

With our new printer design almost completed, the electronics team is working hard at installing all our components into the machine. This includes soldering wires together, hooking parts up, and screwing in our electronics to the wall. We centralized most of our voltage supply wires onto one circuit board, which can fit right onto our Arduino. In addition, we discovered a way to control our power supply unit directly with our on-button, which eliminates the need for more complicated wiring.

Although this will likely be our final design for the school year, we look forward to continuing our work on the printer over the summer, where we will hopefully improve it with even more electronics and hardware.

Tuesday, May 27, 2014

The Never Ending Story

Posted on 5/27/2014 07:20:00 PM by Unknown with No comments

As the year in EDD (and highschool) comes to a bittersweet close and we prepare for our final presentation on June 17th, a small group looks to continue the Charlie project post-graduation. A small group, mostly consisting of build team members looks to continue the project, building a business plan, a go to market plan, promotional materials, as well as finishing and optimizing what we already have in the way of a product. We aim to launch a Kickstarter/crowd-funding campaign for a multitude of reasons. Through this campaign, we will be able to raise money to finish the product, as well as create and develop ways to repeatedly manufacture the printer, generate interest, and gauge how much interest there is in what we are able to bring to the table. We understand that what we currently have is not invention, but does bring about many innovations, as well as combining many existing ideas into one package, as we aim to bring more features in the future.

As the year in EDD (and highschool) comes to a bittersweet close and we prepare for our final presentation on June 17th, a small group looks to continue the Charlie project post-graduation. A small group, mostly consisting of build team members looks to continue the project, building a business plan, a go to market plan, promotional materials, as well as finishing and optimizing what we already have in the way of a product. We aim to launch a Kickstarter/crowd-funding campaign for a multitude of reasons. Through this campaign, we will be able to raise money to finish the product, as well as create and develop ways to repeatedly manufacture the printer, generate interest, and gauge how much interest there is in what we are able to bring to the table. We understand that what we currently have is not invention, but does bring about many innovations, as well as combining many existing ideas into one package, as we aim to bring more features in the future.Saturday, May 24, 2014

Congratulations to our Fellow InvenTeams!

Posted on 5/24/2014 11:52:00 AM by Unknown with No comments

Congratulations to the InvenTeams of Natick High School and Newton North High School on their achievements this year and their invitation to the White House Science Fair. It's always exciting to see other InvenTeams making the news, and we wish them the best of luck!

(Sections from the press release)

"Students from Natick High School and Newton North High School, both in Massachusetts, will travel to the fourth White House Science Fair to showcase their Lemelson-MIT InvenTeam projects to President Obama on Tuesday, May 27. The students will join more than 100 other students from around the country selected to participate in the event, which recognizes winners from a broad range of science, technology, engineering, and math (STEM) competitions.

The White House Science Fair fulfills a commitment the President made at the launch of his Educate to Innovate campaign in November 2009 - to inspire boys and girls to excel in math and science. The President noted at the start of this program, “If you win the NCAA championship, you come to the White House. Well, if you're a young person and you produce the best experiment or design, the best hardware or software, you ought to be recognized for that achievement, too.”

The students from Natick and Newton North are honored for their achievements as 2012-2013 Lemelson-MIT InvenTeam grant recipients from the Lemelson-MIT Program. The InvenTeam initiative inspires young people to pursue creative lives and careers through invention. InvenTeams are granted up to $10,000 each to conceptualize, design and build technological solutions to real-world problems.

Katelyn Sweeney and Olivia Van Amsterdam will represent the Natick High School InvenTeam. The team developed a remotely operated vehicle (ROV) for ice search and rescue dive teams. The land vehicle will quickly traverse the ice and lower a submersible detection device, which will assist a dive team when searching for objects or bodies in dangerously cold waters with temperatures of 33 – 45°F. Katelyn and Olivia have been instrumental in the filing of a U.S. utility patent for their device. Felege Gebru and Karen Cheuk-Wing Fan will represent the Newton North High School InvenTeam. The team developed a pedestrian alert system to be used in Addis Ababa, Ethiopia, to alert crossing pedestrians of approaching vehicles, increasing pedestrian safety. Felege shared his firsthand knowledge of the dangers that pedestrians encounter in his home country of Ethiopia and the InvenTeam has partnered with a sister school in Ethiopia to inform their understanding of the problem and guide the design. "

(Sections from the press release)

"Students from Natick High School and Newton North High School, both in Massachusetts, will travel to the fourth White House Science Fair to showcase their Lemelson-MIT InvenTeam projects to President Obama on Tuesday, May 27. The students will join more than 100 other students from around the country selected to participate in the event, which recognizes winners from a broad range of science, technology, engineering, and math (STEM) competitions.

The White House Science Fair fulfills a commitment the President made at the launch of his Educate to Innovate campaign in November 2009 - to inspire boys and girls to excel in math and science. The President noted at the start of this program, “If you win the NCAA championship, you come to the White House. Well, if you're a young person and you produce the best experiment or design, the best hardware or software, you ought to be recognized for that achievement, too.”

The students from Natick and Newton North are honored for their achievements as 2012-2013 Lemelson-MIT InvenTeam grant recipients from the Lemelson-MIT Program. The InvenTeam initiative inspires young people to pursue creative lives and careers through invention. InvenTeams are granted up to $10,000 each to conceptualize, design and build technological solutions to real-world problems.

Katelyn Sweeney and Olivia Van Amsterdam will represent the Natick High School InvenTeam. The team developed a remotely operated vehicle (ROV) for ice search and rescue dive teams. The land vehicle will quickly traverse the ice and lower a submersible detection device, which will assist a dive team when searching for objects or bodies in dangerously cold waters with temperatures of 33 – 45°F. Katelyn and Olivia have been instrumental in the filing of a U.S. utility patent for their device. Felege Gebru and Karen Cheuk-Wing Fan will represent the Newton North High School InvenTeam. The team developed a pedestrian alert system to be used in Addis Ababa, Ethiopia, to alert crossing pedestrians of approaching vehicles, increasing pedestrian safety. Felege shared his firsthand knowledge of the dangers that pedestrians encounter in his home country of Ethiopia and the InvenTeam has partnered with a sister school in Ethiopia to inform their understanding of the problem and guide the design. "

Thursday, May 22, 2014

The Home Stretch

Posted on 5/22/2014 10:41:00 PM by Unknown with No comments

As our senior year is coming to a close, our final printer is beginning to take shape. All of the acrylic has been laser cut and dry-fitted together, almost ready for completion. On electronics team, we have been hard at work finalizing all of the wiring for the printer. Using the wiring diagram we drafted earlier in the year, we have begun to connect all of the wires to the arduino shield and power supply. After the completion of that, all we have left is to mount everything inside of the printer. I can see the final product coming together, and it is exciting to see all of our work paying off.

Monday, May 19, 2014

Sticking Together

Posted on 5/19/2014 04:52:00 PM by Unknown with No comments

Now that our base incorporates a puzzle piece design instead of using angle bars and bolts, we had to figure out the right glue to use to strengthen the structure. We started off by using acrylic glue. We had trouble with the consistency from the start. The glue was very thin and hard to control, and even pouring the glue into the application bottle was difficult. But after some practice we perfected our skill of acrylic gluing. We found that the glue was very strong and when trying to break the bond, the actual piece of ¼ inch acrylic snapped before the joint did.

Next we tried super glue. We found that super glue was visible and was harder to apply since it was much thicker. Also, when trying to break the joint gave way under a lot less pressure.

Because of this testing we decided on strengthening our base by using acrylic glue at the joints.

Saturday, May 17, 2014

An EYE Update

Posted on 5/17/2014 03:27:00 PM by Unknown with No comments

Recently, EYE has been making amazing progress! Check out these two videos below for what they have been up to, and stay tuned for more information on the upcoming EYES program on June 14th.

Progress report: https://www.youtube.com/watch?v=EgHDwHY_1lI

April 5th EYES Program: https://www.youtube.com/watch?v=GLw-owwjeNI

Progress report: https://www.youtube.com/watch?v=EgHDwHY_1lI

April 5th EYES Program: https://www.youtube.com/watch?v=GLw-owwjeNI

Tuesday, May 13, 2014

Integrate (in't it great?)

Posted on 5/13/2014 09:55:00 PM by Unknown with No comments

As our project comes to its conclusion, it's time for all the teams to coordinate and build the

final machine. The build team and electronics team are currently figuring out how everything will be placed inside the printer, so all the parts and devices will run smoothly. The power button has been soldered to wires, and we have successfully integrated a MOSFET (a type of transistor) into our power supply circuit, since multiple voltages will be used.

As the school year starts coming to an end, we hope our project will be ready to print and present as soon as possible. To do this, we will have to create our final circuit design and figure out how it will fit in our machine, as well as test our software with the completed machine. Now more than ever, this project is a team effort.

As the school year starts coming to an end, we hope our project will be ready to print and present as soon as possible. To do this, we will have to create our final circuit design and figure out how it will fit in our machine, as well as test our software with the completed machine. Now more than ever, this project is a team effort.

Thursday, May 8, 2014

Editing Software

Posted on 5/08/2014 08:58:00 PM by Unknown with No comments

The Software Team has been hard at work these past few weeks. Recently we were able to complete a settings editor page where the user can change printer features such as the printer name, user name, printer resolution and the layer depth. This page can allow the user to have further control over printing. Another task that we have been working on is the ability to have multiple templates and recent templates that the user can access. This can allow the user to print a large quantities of the same part very quickly. The Software team has been working very hard these past few weeks and we hope to continue our progress into the last few weeks to further enhance the interface and the usability for the user.

Friday, May 2, 2014

The Final Printer

Posted on 5/02/2014 10:12:00 PM by Unknown with No comments

A little over a week after making the decision to go with the new design, the final Inventor drawings have been finished. The final prototype has a few major differences from its predecessor. First off, the projector is now pointed downward with the image bouncing off of two mirrors. To fix the issues with the last prototype the Z-table design has been overhauled, now being attached to a square rod that spans the length of the resin pool and slides up and down the guide rods on linear ball bearings. It is still driven by a stepper motor and threaded rod. The acrylic shell will be attached via a puzzle-piecing and gluing method. Lastly, a slimmed down resin pool takes up less space. These changes make for a different look, and allow for a smaller, improved machine.

Looking forward, we aim to have it built, electronics hooked, and begin final testings within the month.

Looking forward, we aim to have it built, electronics hooked, and begin final testings within the month.

Wednesday, April 30, 2014

Cycling to the Finish Line

Posted on 4/30/2014 02:20:00 PM by Unknown with No comments

Come on down to the Saratoga Cycling Studio to help support your favorite engineers! On Thursday, May 8, there will be a donation spin to help benefit our class! If you click on the link below, scroll over to May 8, and click the donation spin button for 3:30 pm, you can sign up for our class. When you do this, please note that we are collecting donations on the day of the event, and would appreciate $15, but more would be such a great help to finishing touches on our project.

Thank you so much!

https://clients.mindbodyonline.com/ASP/home.asp?studioid=25286

Thank you so much!

https://clients.mindbodyonline.com/ASP/home.asp?studioid=25286

Tuesday, April 29, 2014

Prototyping the Circuit

Posted on 4/29/2014 09:03:00 PM by Unknown with No comments

The Electronics Team has been hard at work finishing up the design for the basic circuit. While we are waiting for the Build team to finish the frame, we are making a setup of all electrical components that will be inside the printer. The piece we have found most recently is the PNP MOSFET, which will allow the circuits to be run at varying voltages. This device (shown above) allows us to power the gate pin, which will in turn allow current to travel from source to drain. This allows us to run some things (like the stepper motor) at 12V, and others (like the smoke sensor) to be run at 5V. This can all be run from the singular power button that will enable the entire device.

Thursday, April 24, 2014

Brand Spanking New

Posted on 4/24/2014 10:46:00 PM by Unknown with No comments

Our first print was a great accomplishment, we learned a lot and showed that we were capable of printing a three dimensional part, but we know we can make our printer even better. We completely re-designed the printer to be stronger, more accurate, and more compact. The most drastic change in the design will be size. By orienting the projector vertically instead of horizontally, we can eliminate much of the wasted space our old "box" design. The vertical projector will require the use of two mirrors, which need to be perfectly calibrated to avoid distortion. While adding mirrors adds complexity, it saves plenty of space, our new printer dimensions will be about 14"x12"x16", which is a considerable decrease from the old design, which was almost four times the volume.

Our first print was a great accomplishment, we learned a lot and showed that we were capable of printing a three dimensional part, but we know we can make our printer even better. We completely re-designed the printer to be stronger, more accurate, and more compact. The most drastic change in the design will be size. By orienting the projector vertically instead of horizontally, we can eliminate much of the wasted space our old "box" design. The vertical projector will require the use of two mirrors, which need to be perfectly calibrated to avoid distortion. While adding mirrors adds complexity, it saves plenty of space, our new printer dimensions will be about 14"x12"x16", which is a considerable decrease from the old design, which was almost four times the volume.The most prominent feature of our previous printer was the large tower holding the build platform that rises out of the resin pool during printing (we call it the "z-table"). Our X and Y resolution for each layer were nominal, but the resolution in the Z direction suffered due to the design of the z-table mechanics. The long arm which connected the table to the mechanics for motion inside the tower separated the center of mass of the table from the threaded rod and stepper motor; the high torque bound the gear and made motion inconsistent. Our new design will stabilize the z-table by adding guide rails on each side of the table, as well as moving the motion mechanics nearer to the center of mass.

Tuesday, April 22, 2014

A Z-Table-centric Design

Posted on 4/22/2014 04:32:00 PM by Unknown with No comments

Our first print, as many readers know, was relatively successful. However it did reveal problems with the z-table. To print, we improvised on the spot to hold up the heavy z-table structure, but since the z-table was not stable, the design needed to be changed yet again. Over the past week or so we have developed a new design for our printer that works around the issue of our z-table. Our new design has three support points and a more secure locking mechanism involving electromagnets. As soon as the design is finalized this week, the build process will start all over again. The clocking is ticking till our end of the year presentation, but we are confident we can get it done!

Friday, April 11, 2014

Fourth Time's the Charm

Posted on 4/11/2014 03:13:00 PM by Unknown with No comments

The build team is beginning work on the fourth prototype. Handles

have already been heat formed from acrylic, and AutoCad designs are being

created for the rest of the fourth prototype. The fourth prototype will use a

second mirror in order to conserve space. Other improvements to be seen in the

fourth prototype include a sturdier door and lift supports. The Z table and Z tower

will also be redesigned in the new prototype to resolve balance issues and

improve resolution.

Thursday, April 3, 2014

First Print: Success!

Posted on 4/03/2014 10:56:00 PM by Unknown with No comments

Our print deadline today, and as everyone scrambled to tie up loose ends, the group thought the outlook on printing today was rather grim. During class, everyone went into overdrive and made more progress than anyone could have imagined. A new Z table got milled out that would have more structural integrity than the one before which was warped. The new acylic base and top were almost finished and hopefully will done for tomorrow for all the electronics and other components to move into. The electronics and code were also finalized, so it looked like we could print on schedule.

At the end of the school day, we decided to give it a shot. What did we have to lose? We turned on the wooden machine that had rubber bands, super glue, and bolts keeping it together. Filling the resin pool with our new indigo resin, we started printing our default gear template. As it printed, many of us were skeptical about whether we would actually get a gear. When the last layer finished and the Z table rose, we saw it. In resin was the shape of a gear. Initially we thought it was only the first layer that had printed, but as the Z table rose, we realized it did print almost exactly what we wanted. Needless to say everyone is incredibly excited and happy! We are so excited to move on from here, knowing that what we have works so far. We discovered a few kinks that need to be ironed out, but, it can only get better from here!

Tuesday, April 1, 2014

Stepping Up to the Plate

Posted on 4/01/2014 09:55:00 PM by Unknown with No comments

Right now the programming team is working on a settings page interface where the user can change certain aspects of the printer, such as the color, and the layer depth. We are also working with the build team to finalize the stepper motor code, for example when it is given an amount of steps it will move that far. Finally, we are also working on code to implement limit switches so the motor does not go out of range, and code for a rotary encoder to add a check for the position of the motor when it is running. We are hoping to print by 4/3, and we hope to have all of the software optimized by then.

Saturday, March 29, 2014

Take Four!

Posted on 3/29/2014 07:08:00 PM by Unknown with No comments

The resin pool is obviously a very important part of the 3D printer, seeing that it has to contain the resin that a part is printed from. Recently advancements have been made in its functionality and its aesthetics. The aluminum "exoskeleton" for the pool is now made from an aluminum sheet that is 1/8th of an inch think instead of 1/16th thick. Also, the C-Channels that support the glass walls have been switched out for angle bars and the glass walls are now 1.5 inches tall instead of just 1 inch. We are going to continue to use borosilicate glass for the bottom and we are currently doing on a silicone coating rather than Sylgard.

Thursday, March 27, 2014

Money Money Money

Posted on 3/27/2014 07:56:00 PM by Unknown with No comments

With the final stretch to our end of the year deadline quickly approaching, the marketing team is looking for opportunities to get our product on the market. We have recently contacted an artist to finish our logo, and we should have samples in the next few days.

There is still time to continue fundraising, and it is necessary that we continue to have an income of funds, through fundraisers, grant applications and local company donations. There has been so many generous donors and supporters through out the school year, and we are very thankful, because it has provided us with the means to get this far in the project.

There is still time to continue fundraising, and it is necessary that we continue to have an income of funds, through fundraisers, grant applications and local company donations. There has been so many generous donors and supporters through out the school year, and we are very thankful, because it has provided us with the means to get this far in the project.

Monday, March 24, 2014

Smoking Hot

Posted on 3/24/2014 08:42:00 PM by Unknown with No comments

With the machine's core components being assembled and integrated, the electronics team is now focusing on safety mechanisms. This includes limit switches for the Z-table arm, laser indicators in our resin pool, and smoke detectors to be installed inside the machine. Similar to the devices you might find in your ceiling, these smoke sensors will shut off the machine if something inside starts burning (which might be a sign of trouble!).

However, the resin we are currently using also appears to let off gas while being cured, which might activate the smoke detectors. Further testing of these devices will be necessary to determine if they will be suitable. With our machine being close to completion, we want to make our first print as safe as possible.

However, the resin we are currently using also appears to let off gas while being cured, which might activate the smoke detectors. Further testing of these devices will be necessary to determine if they will be suitable. With our machine being close to completion, we want to make our first print as safe as possible.

Friday, March 21, 2014

Finally Good News

Posted on 3/21/2014 08:57:00 AM by Unknown with No comments

Yesterday the class made tons of progress with our printing process. We tested curing a new type of resin (MakerJuice brand, cool indigo color) and it cured within seconds, much faster than the stuff we had been using before. Also, the smell on this resin is a lot less severe than the Solarez. When the resin was done, a 5-10 minute butanol bath finished up the job removing any excess oily resin. As soon as the resin was tested, the projector began to project some images to print and was able to show the different layers in our printing process.

During the resin test, we also tested the resin under the black light and the resin did not react.

After so many set backs, the group had a great day and our goal is to print during the first week of April. Hopefully, it won't be anything close to an April Fool's Day joke though!

Tuesday, March 18, 2014

Lighten Up!

Posted on 3/18/2014 04:43:00 PM by Unknown with No comments

For the Z-table, arm and tower our goal has been to even further lighten up the design and improve the overall sturdiness. We have moved away from our wooden design to a more professional looking aluminum one. The whole Z-tower has been redesigned to work with aluminium. This has improved helped improve the stiffness of the tower so when the actual z-table is attached it will not wobble at all. The Z- tower arm has also moved away from the wooden design to an aluminium one. It consists of a hollowed out aluminium bar witch attaches to the lead screw with a custom made lead screw nut that helps maintain the precision 3D printing requires. The last piece we have been working on is Z-table itself. The new design consists of easy to machine chemical resistant plastic that is going to be pocketed by the mill into a hollow box. This will help reduce weight without sacrificing sturdiness. One of our biggest obstacles in our new design has been getting the mill to work. However within the next two days it should be running and milling out our Z-table. From here we plan to assemble all the pieces of our new Z-table and start our first print within two weeks.

Thursday, March 13, 2014

Upcoming Vision

Posted on 3/13/2014 08:42:00 PM by Unknown with No comments

The past two weeks have been great for the EYE team! We have been working to plan for the April as well as the June program by ordering the necessary supplies and gathering volunteers. We launched registration for our April Program and have already filled all 150 available slots! We also have a growing waiting list (60 kids and counting!). In addition to implementing additional elementary engineering programs, we are working on evaluating the programs that currently exist and creating guides for how to run future programs. Our primary goal is that the Educating Young Engineers organization will continue helping the Saratoga Springs City School District (and beyond) excite the next generation of problem solver and innovative thinkers. To achieve this we are so happy to have three interns, they are going to be the next generation of EYE leaders!

Wednesday, March 12, 2014

LEGO Playground

Posted on 3/12/2014 09:44:00 PM by Unknown with No comments

Tuesday, March 11, 2014

Resin the Bar

Posted on 3/11/2014 09:15:00 PM by Unknown with No comments

Today in class was a fairly productive day for the build and electrical teams. We (as the electronics team) wanted to test the accuracy of the infrared distance sensor that will be used to find the remaining amount of resin. We have been doing some tests using water instead of resin, and they showed that our sensor may not be accurate enough. Just to verify, we brought the current prototype into a darkroom, and tested the machine with the resin. When the group of electrical and build team members set everything up, we realized that we didn’t have enough resin on hand to accurately test the distance sensing. Luckily, the day was not lost, because we tested in the real resin pool. This allowed us to see how the pump works, as well as the Sylgard layer on the pool. Both worked great, and our day became a great success.

Today in class was a fairly productive day for the build and electrical teams. We (as the electronics team) wanted to test the accuracy of the infrared distance sensor that will be used to find the remaining amount of resin. We have been doing some tests using water instead of resin, and they showed that our sensor may not be accurate enough. Just to verify, we brought the current prototype into a darkroom, and tested the machine with the resin. When the group of electrical and build team members set everything up, we realized that we didn’t have enough resin on hand to accurately test the distance sensing. Luckily, the day was not lost, because we tested in the real resin pool. This allowed us to see how the pump works, as well as the Sylgard layer on the pool. Both worked great, and our day became a great success.Monday, March 3, 2014

Charlie Takes 3D Systems

Posted on 3/03/2014 02:22:00 PM by Unknown with No comments

Currently, the Marketing Team is researching how to successfully market a 3D printer. The market is very competitive and our product has great features that will offer new opportunities to current printer users. We have been studying our biggest competitor, and leading 3D printer developers, 3D Systems, and how they are so successful with each of their products. We are also researching our other main competitors and learning what their consumers like, dislike, love and hate about their product(s).

Currently, the Marketing Team is researching how to successfully market a 3D printer. The market is very competitive and our product has great features that will offer new opportunities to current printer users. We have been studying our biggest competitor, and leading 3D printer developers, 3D Systems, and how they are so successful with each of their products. We are also researching our other main competitors and learning what their consumers like, dislike, love and hate about their product(s).We have found an artist to design our logo - Aliki Kotsakis. She is a former Project Lead the Way student and is a very talented artist. We hope to have a finalized logo by the end of April.

Mid-Year Build Team Report

Posted on 3/03/2014 02:14:00 PM by Unknown with No comments

Friday, February 28, 2014

Testing the Waters

Posted on 2/28/2014 10:15:00 PM by Unknown with No comments

In the electronics world, we have been testing our infrared distance sensor (pictured above), which will be used to test how much resin is in the pool. We have confirmed it does perform as expected with translucent liquid, but questions remain about its accuracy. Too much or too little resin could cause problems (anywhere from mild to serious), and it is uncertain if our current devices could measure it precisely enough.

In addition, we have make progress in our ultimate goal: integrating our parts into the machine itself. Our stepper motor has been successfully mounted, and we will soon begin running and testing it with all our moving parts. We hope to have a working movable table by the end of the month.

In addition, we have make progress in our ultimate goal: integrating our parts into the machine itself. Our stepper motor has been successfully mounted, and we will soon begin running and testing it with all our moving parts. We hope to have a working movable table by the end of the month.

Tuesday, February 25, 2014

GUI

Posted on 2/25/2014 11:25:00 PM by Unknown with No comments

The software team has been up to a lot lately. From adding new features to the GUI to controlling the stepper motor the software team has been working on many essential features for Charlie. From the Graphical user interface standpoint a new print viewer has been constructed so that the user can see a nice organized print progress and data screen showing helpful info such as the resin levels and time until completion. After testing a few other styles we found that dynamic sizers work best for laying out all of the spacers and widgets found in the print viewer. Through the wx python library we were able to also use a progress bar that will eventually be programmed to give the user an actual visual representation of the progress of the printing. On the more electronic side with the stepper motor the software team has completely switched to using arduino to program the stepper motor and the microcontroller. Using arduino we hope to have the motor receive a certain number of steps and execute those steps. Another great accomplishment of the software team was the creation of 3D STL files that can be produced. By taking user entered input our program can create a 3D image for gears of the gear that the user wants to print. These past few weeks have led to the creation of many important features and we hope to continue this on to the future with more amazing features.

Tuesday, February 18, 2014

EYES

Posted on 2/18/2014 10:08:00 PM by Unknown with No comments

Wednesday, February 12, 2014

Forming a Plan

Posted on 2/12/2014 08:50:00 PM by Unknown with No comments

Recently,

the CAD team had been trying to come up with a fresh and sleek design to set

out printer apart from those that already exist in the market. After a few

sketches and weeks of CAD design we finally settled on what we believe combines

all of the best ideas we came up with. However, with the completion of this

challenge, a new one arose. The design calls for essentially a rectangular

prism, with two of the sides joining in a sloping curve instead of a simple

edge. Because this would have to be made out of acrylic, we had to decide

how we were going to tackle it. We looked up the cost of having our part custom-made,

and upon seeing the price we decided that we would task ourselves making the

piece on our own. We knew the process slightly: we would need to heat up a

sheet of acrylic until it was at a point where it could be shaped without being

completely melted, and then place it on a mold for it to form to. It didn’t sound very difficult, and we had watched a few videos demonstrating

the process. However, we all knew that nothing is ever as easy as it looks, not

to mention none of us had any experience with type of molding process, known as

heat-forming. Luckily, we had just recently taken a tour of a GE facility, and

met many engineers who did have experience heat-forming. So, we called one of

these engineers up and he was able to give us a step-by-step process of what to

do, complete with cautions about some common mistakes and potential errors that

could occur during the forming. So after a little brainstorming, we decided

we’d make the curve out of layers of laser-cut wooden parts stacked side by

side. The engineer did warn that the acrylic would mold to whatever shape we

pressed in against, though, so we decided to place a smooth piece of vinyl on

the mold so there wouldn’t be any unwanted ridges or bumps. We have already

made the curve to our desired dimensions, and once we attach the straight

pieces to each end we will be ready to mold.

Recently,

the CAD team had been trying to come up with a fresh and sleek design to set

out printer apart from those that already exist in the market. After a few

sketches and weeks of CAD design we finally settled on what we believe combines

all of the best ideas we came up with. However, with the completion of this

challenge, a new one arose. The design calls for essentially a rectangular

prism, with two of the sides joining in a sloping curve instead of a simple

edge. Because this would have to be made out of acrylic, we had to decide

how we were going to tackle it. We looked up the cost of having our part custom-made,

and upon seeing the price we decided that we would task ourselves making the

piece on our own. We knew the process slightly: we would need to heat up a

sheet of acrylic until it was at a point where it could be shaped without being

completely melted, and then place it on a mold for it to form to. It didn’t sound very difficult, and we had watched a few videos demonstrating

the process. However, we all knew that nothing is ever as easy as it looks, not

to mention none of us had any experience with type of molding process, known as

heat-forming. Luckily, we had just recently taken a tour of a GE facility, and

met many engineers who did have experience heat-forming. So, we called one of

these engineers up and he was able to give us a step-by-step process of what to

do, complete with cautions about some common mistakes and potential errors that

could occur during the forming. So after a little brainstorming, we decided

we’d make the curve out of layers of laser-cut wooden parts stacked side by

side. The engineer did warn that the acrylic would mold to whatever shape we

pressed in against, though, so we decided to place a smooth piece of vinyl on

the mold so there wouldn’t be any unwanted ridges or bumps. We have already

made the curve to our desired dimensions, and once we attach the straight

pieces to each end we will be ready to mold.Tuesday, February 11, 2014

EYES, Saratoga Reads, and STEM Expo

Posted on 2/11/2014 04:14:00 PM by Unknown with 1 comment

February has only just begun, but the Educating Young Engineers team has already accomplished so much! We started out the month with our primere Saturday Engineering Program on February 1! The event went amazingly well! We were extremely impressed with all of the young engineers solutions to our challenges. We are also extremely appreciative of all of the volunteers who made the day possible, together we raised $2,400 to excite many more young engineers! We have decided that we will be putting on a very similar program in April, for the children who were on our waiting list or were unable to attend. Then in June we are going to do a mega program, open to even more young engineers and with all new challenges! In addition to putting on our own engineering day, we also helped support local events. On Saturday February 8 we had a station at the Saratoga Reads event. At this event the children all came with LEGO creations that they showed off to other excited LEGO creators. We were there to show how LEGOs can come to life with the WeDo kits and programming software. Then on Monday February 10 we had a station at the STEM expo at Division Street Elementary school. We showcased the wind tunnel and had the children test out a variety of different flight mechanisms. They determined which could fly the best by watching how high the flight mechanism flew and how many little people it could carry! We are very happy with how rapidly our EYE organization is expanding and have been extremely grateful to play a role in such amazing events.

If you would like to read a news article about the Saturday Engineering Day you can click on the link that follows:

Thursday, February 6, 2014

A Step in the Right Direction

Posted on 2/06/2014 09:30:00 PM by Unknown with No comments

The electronics team has been working closely with Mike and Isaac from the programming team, and we hope to get the stepper motor fully working with their driver class soon. This whole process has hit a few delays, but it should be done within the next few days. We have also been working to integrate the stepper motor with the z-table, which will ultimately move the part. We attached on the motor to the z-table system today, and next class we will be able to calibrate the distances for the steps and fine tune the program and microstepping. We think our project is going along quite nicely, and we look forward to seeing everything come together in the near future.

Tuesday, February 4, 2014

Who Wants to be an Engineer?

Posted on 2/04/2014 08:27:00 AM by Unknown with No comments

While the high school was out of classes for Regents and midterm testing, a group of Project Lead the Way students re-visited the middle school to talk about the technology courses the high school has to offer to our upcoming freshman class. Eight students and two high school tech teachers explained what each class entailed and described some of the activities that went on in the classroom. Our high school students were even able to show some of their projects from each class, getting excited about what they were able to create. After the presentation, the middle school students spent the second half of the period asking questions either about PLTW or about high school in general. The questions ranged from, "Does the high school have vending machines?" to, "How close is a robot to human intelligence?"

During some down time we even got to visit a 7th grade tech class and help out with their projects and around the classroom in general.

The prospects for next year's PLTW freshmen class and we can't wait to see them!

During some down time we even got to visit a 7th grade tech class and help out with their projects and around the classroom in general.

The prospects for next year's PLTW freshmen class and we can't wait to see them!

Friday, January 31, 2014

EDD Takes GE

Posted on 1/31/2014 09:26:00 PM by Unknown with No comments

This past Thursday, General Electric Research and Development was kind enough to offer the InvenTeam the opportunity to tour their buildings. We mainly toured their rapid prototyping, and 3D manufacturing facilities. The class first met with two mechanical engineers, working with medium sized resin and polymer-based printers, much bigger than machines like the MakerBot, yet still manageable. These engineers allowed us to ask questions, and showed us the project they are currently working on, such as the new Leap jet engine (due out in 2016). From there the class went to a building that housed a metal SLM 3D printer, which lays down layers of extremely fine cobalt chrome-moly and uses either a 400W or 1000W laser to weld the metal together. After getting a look at these incredibly intricate machines, we were shipped off to a more industrial building, which housed extrusion machines and a cold spray “jet”. For an explanation of cold spray, The Slow Mo Guys and GE on Youtube have a great video of the exact machine that the team was introduced to. After our amazing tour, the InvenTeam was treated to lunch, and we were even joined by Juan Pablo, our new friend from GE! Just before leaving, we received a presentation about the future of GE engineering, and a brief outline of today’s focuses in GE and engineering as a whole, one of which was 3D printing. The whole team would like to thank GE again, for their hospitality and for the wonderful demos that many of GE engineers gave us. We hope to visit again in the future and can't wait to show them what we've done at the end of the year!

This past Thursday, General Electric Research and Development was kind enough to offer the InvenTeam the opportunity to tour their buildings. We mainly toured their rapid prototyping, and 3D manufacturing facilities. The class first met with two mechanical engineers, working with medium sized resin and polymer-based printers, much bigger than machines like the MakerBot, yet still manageable. These engineers allowed us to ask questions, and showed us the project they are currently working on, such as the new Leap jet engine (due out in 2016). From there the class went to a building that housed a metal SLM 3D printer, which lays down layers of extremely fine cobalt chrome-moly and uses either a 400W or 1000W laser to weld the metal together. After getting a look at these incredibly intricate machines, we were shipped off to a more industrial building, which housed extrusion machines and a cold spray “jet”. For an explanation of cold spray, The Slow Mo Guys and GE on Youtube have a great video of the exact machine that the team was introduced to. After our amazing tour, the InvenTeam was treated to lunch, and we were even joined by Juan Pablo, our new friend from GE! Just before leaving, we received a presentation about the future of GE engineering, and a brief outline of today’s focuses in GE and engineering as a whole, one of which was 3D printing. The whole team would like to thank GE again, for their hospitality and for the wonderful demos that many of GE engineers gave us. We hope to visit again in the future and can't wait to show them what we've done at the end of the year!Monday, January 27, 2014

Saturday Engineering Program

Posted on 1/27/2014 11:36:00 PM by Unknown with No comments

This January was a very busy month for the Educating Young Engineers group! Our most amazing accomplishment was filling up all ONE- HUNDRED slots for our premier Saturday Engineering Program! A major priority of the EYE group has been organizing all aspects for our Engineering Day. We have been working to plan out all of the modules that the participants will go through. We have decided on a Wind Tunnel, a Marshmallow Catapult, a Toothbrush Robot, and an Egg Crash Car module. The Saratoga Springs technology teachers have been working to gather all of the supplies necessary for their stations. The EYE group has been providing teacher support by building the bases for the Egg Crash Cars, printing posters, and shopping for supplies! We are excited and a little bit nervous for our first Saturday Engineering Day, but we have faith in our volunteers and participants that this day will ultimately be a success!

Thursday, January 23, 2014

Charlie's Personality

Posted on 1/23/2014 05:36:00 PM by Unknown with No comments

As part of our marketing strategy, we want each printer to be unique. We want individuals to build a personal connection with their machines, as exemplified by our use of names such as "Charlie". To accompany the various names and personalities of our printers, we have designed our software to have different color schemes, some of which are pictured above. These color schemes will match the paint job on the robot.

In addition to changing colors, our application can change size. It is designed to dynamically adapt to various screen sizes, so users will have a consistent experience regardless of form factor. The menus, buttons, and pages automatically fill the screen, and use the space they are assigned as effectively as possible, so buttons are always as large as possible relative to screen size.

Tuesday, January 21, 2014

A Z-Table in Z-Making

Posted on 1/21/2014 06:36:00 PM by Unknown with No comments

For the z-table we have been working to improve our initial z-table design which consisted of a removable U-shaped z-table surrounding a box that was permanently connected to the printer. Our goal was to lighten up this design, decrease the build space to fit the aspect ratio of the projector, create a sturdy set-up that will allow for precise printing, and have an easier way to detach the z-table from the printer.

We have been able to lighten up our z-table design by using laser cut wood to make up most of the z-table. Also, by decreasing the size to match the aspect ratio we were able to shed some weight. We have also improved the design for removing the z-table to one that uses a large hand twist-able screw for easy removal of the table. Currently, we are still having difficulties making the z-table completely sturdy. The torque exerted by the whole table on the wooden base and on the connection point to the threaded rod are causing a little bit of wobble, something that needs to be fixed before the table is print ready. Next we are going to work on refining our prototype to a point where we will be able to use it for printing and from there amp up the quality on all accounts of the printer.

Thursday, January 16, 2014

Time to CR8!

Posted on 1/16/2014 03:40:00 PM by Unknown with No comments

Introducing... Charlie CR8, the name of the EDD class of 2014's 3D printer! Why is Charlie so special? Due to our goal of creating a personal machine, we have decided that Charlie is the best name for our final product. For every printer we sell, our consumer is going to receive a uniquely named product. To keep from confusion however, they all will end in CR8 (create), because it's the family's last name.

Introducing... Charlie CR8, the name of the EDD class of 2014's 3D printer! Why is Charlie so special? Due to our goal of creating a personal machine, we have decided that Charlie is the best name for our final product. For every printer we sell, our consumer is going to receive a uniquely named product. To keep from confusion however, they all will end in CR8 (create), because it's the family's last name.We wanted our 3D printer to stand out from our competition and Charlie definitely does. By purchasing our product, you will join the InvenTeam family, and that helps show the consumer that they are not just a consumer. Everyone who supports our product is an important part of our project.

Stay tuned for the announcement of our upcoming website, CR8withCharlie.com.

Tuesday, January 14, 2014

Mid-Year Presentation

Posted on 1/14/2014 09:59:00 PM by Unknown with No comments

For this evening's presentation, each group made a presentation detailing what they have been doing from the beginning of this year to now, our half way point. Not only did our presentation help the groups organize their progress, but also allowed everyone to improve upon their public speaking skills. Each student was able to showcase what they have been working on, and also showcase their knowledge of the project as a whole as unanticipated questions were fired around.

Even more exciting yet from today's presentation was the début of our printers name:

Charlie CR8

Each printer will have an individual name as to personalize the user experience. To add a commonality, each printer has the same last name (model name), Cr8-- create. When a customers purchases one of our printers, they will be expanding the Inventeam family, an experience unlike any of our competitors.

With future goals in mind and suggestions noted, it is time to Cr8!

Friday, January 10, 2014

Taking the Next Steps

Posted on 1/10/2014 08:46:00 PM by Unknown with No comments

With our prototype slowly coming together, there are more parts to test and integrate than ever. From the sensors to the motors and pumps, we certainly have a long road ahead of us.

Thursday, January 9, 2014

Ready, Set, Slice!

Posted on 1/09/2014 08:16:00 PM by Unknown with No comments

One of the crucial elements of a 3D printer's software is the process of taking a 3D model file (usually in the form of a .stl file), and figuring out how to go about printing each layer.

Since we're going to be projecting UV light onto resin to create thin layers of polymer, we need to generate cross sections of whatever we're printing. This process is known as slicing.

We've utilized some existing libraries to handle some of the heavy mathematical lifting involved, namely a toolset known as Skeinforge. From here, we need to turn the many slices into image files to be projected. To do this, we generate an empty image file and draw to it, tracing around the slice we've created.

Once this is done, any file will be able to be sent to print!

Monday, January 6, 2014

Reflecting on Progress

Posted on 1/06/2014 10:08:00 PM by Unknown with No comments

Today was a busy day for the Build Team as our deadline draws near to finish up the physical construction of our first prototype. New parts were printed using the laser cutter and team members began to piece together some of the last components of Prototype 1. Additional research was also done on the UV filter in the projector, which will be crucial for the machine to print. However, this isn't the only roadblock we have found with the projector. With the previous version of the 3D printer, too much space was needed for the projector image to cover the entire build space of the resin pool. To solve this dilemma it was decided that the projector would be laid on its side and a mirror would be put in place (at a perfect 45 degree angle) that would reflect the image up to the resin pool. Though the math was not as simple as originally thought, we were able to determine the exact dimensions of the mirror that was needed and placement of the resin pool in relation to the projector. This seems to be a much better alternative as it now fits in a more reasonable area. Another problem we encountered was we found that our first model was much too large and the base contained far too much unused space. Changes were made to eliminate unnecessary space and reduce the dimensions to a much more appealing size. Sometimes bigger isn't better.

Subscribe to:

Posts (Atom)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.JPG)

.jpg)